Please Choose Your Language

+86-512-52396378

sales@szuniking.com

sales@szuniking.com

1 Longteng Rd, Tonggang Industrial Park, Changshu ETDZ, Jiangsu Province, China 215511

Views: 0 Author: Site Editor Publish Time: 2025-09-01 Origin: Site

Polycarbonate is a strong and clear plastic. You often see it in things that must be tough and see-through. It is used in protective gear, electronics, and medical tools. Polycarbonate is different from other plastics because of its special structure and how well it works.

Characteristic | Description |

|---|---|

Molecular Structure | Made from bisphenol-A with carbonate links |

Aromatic Rings | Make it stronger and help it resist hits |

Amorphous Nature | Gives it great clarity and keeps it stable with heat |

High Impact Resistance | Handles tough situations without breaking |

Optical Clarity | Makes it more see-through and lets light pass easily |

Thermal Stability | Keeps its shape even when it gets hot |

Polycarbonate’s strength, clear look, and stability help in many real-life uses.

Polycarbonate is a tough and see-through plastic. It works well for safety gear, electronics, and medical tools.

It does not break easily because it resists impacts. This helps keep people safe in many uses.

Polycarbonate lets a lot of light pass through. It allows 88% of light to go in, so it can replace glass.

This material can be shaped in many ways. It fits many industries like cars and building.

Polycarbonate is good for the environment because it can be recycled. This helps make manufacturing more sustainable.

You see polycarbonate almost every day. You might not notice it. Polycarbonate plastic is very strong and clear. It is an engineering material. You find it in safety glasses. It is also in electronics and car parts. The chemical structure has carbonate groups. These groups make it tough and stable. Manufacturers make polycarbonate by mixing Bisphenol A and phosgene. They use a step-growth polymerization process. This creates a clear and strong material. It does not break easily. It can handle heat.

Polycarbonate has an interesting history. Scientists made it first in 1898. In 1928, DuPont researchers found it while studying other plastics. By 1953, Hermann Schnell at Bayer and Dan Fox at General Electric made new versions. These could be produced in large amounts. Production began in the late 1950s. In 1971, polycarbonate became even clearer. Today, you see many kinds of polycarbonate in products.

Did you know? Polycarbonate is so strong that people use it instead of glass where safety is important.

Polycarbonate has special features. These make it useful for many things. You can see through it easily. It looks like glass. It stays strong from -20°C to 140°C. You can use it in cold and hot places. Polycarbonate plastic almost never breaks. You can trust it in tough situations.

Here are some basic features:

High impact strength means it does not break easily.

Good dimensional stability helps it keep its shape.

It works up to 120°C for a long time.

It resists cold with an embrittlement temperature of -100°C.

Low water absorption keeps it strong for years.

It stays stable in acid and oil.

You can mold it by injection, extrusion, or blow molding.

You can pick different types of polycarbonate for your needs. Some types block UV light better. Others are clearer or stronger. Polycarbonate is special because it is tough, clear, and flexible. People use it instead of glass, PMMA, and PE in many industries.

Feature | Benefit |

|---|---|

Impact Resistance | Stops things from breaking |

Clarity | Lets you see clearly |

Heat Stability | Works in high heat |

Electrical Properties | Safe for electronics |

Eco-Friendly | Can be recycled |

Polycarbonate is a good choice for products that need to be strong, clear, and safe.

You need tough materials for hard jobs. Polycarbonate is very strong and durable. It is much stronger than other plastics. Polycarbonate is 250 times stronger than glass. Acrylic is only 17 times stronger than glass. Polycarbonate works better than ABS when things get rough. It stays strong even when it gets cold.

You can trust polycarbonate where safety is important. It is used in bulletproof glass and riot shields. You also see it in protective gear. Experts test polycarbonate with ASTM D256 and ISO 180. These tests show polycarbonate does not break easily.

Testing Category | Description |

|---|---|

Ballistic | Tests how well it stops bullets and other impacts. |

Explosive | Checks if it can handle blasts or strong waves. |

Forced Entry | Finds out if tools like hammers can break it. |

Chemical and Flame | Tests if it can stand up to chemicals or heat. |

UL Standard 752 | Measures bullet resistance for safety equipment. |

NIJ 0108.01 | Rates how well it protects against bullets. |

ASTM-1233 | Tests security glass and systems. |

HP White Laboratories | Checks clear materials for barriers and safety. |

ASTM F1233 | Rates security glass for impact and bullet resistance. |

Polycarbonate does not crack or shatter easily. This makes it great for places where safety matters.

You want materials that let light through and stay strong. Polycarbonate is very clear and lets lots of light pass. It lets 88% of light through, so you can see well. Acrylic lets 92% of light through, but polycarbonate protects better.

Feature | Description |

|---|---|

UV Protection | Polycarbonate lenses block all harmful UVA and UVB rays. |

Optical Clarity | They stay clear with little distortion. |

Additional Coatings | Sometimes extra coatings help keep them clear in sunlight. |

Polycarbonate stays clear even after being in the sun for a long time. It does not turn yellow or get blurry. This makes it good for outdoor windows and medical tools. You get both safety and clear views.

You want materials that last a long time. Polycarbonate is durable and stable in tough places. It does not wear out, age, or turn yellow fast. Things made from polycarbonate can last for many years. You see it in outdoor signs and building panels. It is also used in equipment for bad weather.

Polycarbonate can take hits and rough treatment.

It keeps its shape and stands up to bad weather.

Polycarbonate has a melting point of about 288°C (550°F).

It does not change even with lots of heating and cooling.

It stays the same size and shape over time.

Temperature Range (°C) | Temperature Range (°F) | Description |

|---|---|---|

-40 to 130 | -40 to 266 | It stays strong in hot and cold weather. |

Glass Transition Temp (Tg) | 147 | This is when it changes from hard to soft. |

Heat Deflection Temp (HDT) | 130 | It keeps its shape at high temperatures. |

Polycarbonate works well in both hot and cold places. You can count on it for outdoor and tough jobs.

You want a material that works for many things. Polycarbonate is easy to use and shape. You can make it in different ways:

Processing Method | Description |

|---|---|

3D Printing | Lets you make quick models and detailed shapes. |

Injection Molding | Makes exact parts in large numbers. |

CNC Machining | Cuts and shapes sheets for custom parts. |

Polycarbonate is used in cars, electronics, and medical tools. Its features make it good for hard jobs. You can mold, cut, or print polycarbonate for your needs. Polycarbonate fits many uses, whether you need strength, clarity, or flexibility.

Tip: If you want something strong, clear, and stable, polycarbonate is a good pick.

Polycarbonate is in many things you use each day. This plastic is strong and clear. It helps keep you safe and makes life easier. You find it in things that need to be tough, light, and see-through.

Water bottles and baby bottles use polycarbonate. They are almost impossible to break. You do not have to worry if you drop them.

Safety goggles and sports helmets use polycarbonate. It protects you from hard hits during activities.

Eyeglass lenses and sunglasses use polycarbonate film. You see clearly and your eyes are safe from the sun.

Food containers and kitchenware use polycarbonate. It can handle heat and does not break easily.

Power tools and home appliances use polycarbonate. The parts are strong and light.

Note: Polycarbonate film is also used for packaging and labels. It keeps products safe and helps them look nice in stores.

You may not notice, but polycarbonate film covers many things at home. It protects screens on your phone, tablet, and TV. It also lines some furniture and water dispensers. Polycarbonate helps products last longer and work better.

Here is a quick look at how polycarbonate compares to other plastics in household items:

Property | Polycarbonate | Polypropylene |

|---|---|---|

Strength | Exceptional strength | Moderate strength |

Impact Resistance | High impact resistance | Low impact resistance |

Heat Deflection Temp | ~132°C | ~100°C |

Transparency | Glass-like | Opaque |

You get more safety and better use from products made with polycarbonate.

Polycarbonate is important in many industries. You see it in cars, electronics, medical devices, and buildings. Companies pick polycarbonate because it is strong, clear, and easy to shape.

Here is a table showing where you find polycarbonate in different industries:

Industrial Sector | Common Applications |

|---|---|

Construction | Sheet and film for glazing, sound walls, polycarbonate roofs, UV protection, and thermal insulation. |

Automotives and Aerospace | Lighting, headlamp lenses, dashboards, bumpers, bulletproof glass, and architectural glazing. |

Consumer Goods | Power tools, baby bottles, furniture, water dispensers, sporting goods, and medical applications. |

Medical Market | Medical devices, renal dialysis, cardiac surgery products, surgical instruments, IV connection components. |

Polycarbonate film is in electronics and packaging. It covers screens and protects circuits. It keeps devices safe from damage. In cars, polycarbonate shapes body panels, lights, and dashboards. It gives cars better protection and design choices.

Polycarbonate film is important in electronics. It insulates wires and protects small parts. You find it in LED lights, phone cases, and computer housings. Polycarbonate film also helps make flexible screens and touch panels.

In medicine, polycarbonate is used for tools and equipment. It can be cleaned and is safe for the body. Polycarbonate film is used in medical packaging and labels. It keeps tools clean and easy to find.

Did you know? Over 36.5% of the polycarbonate market comes from sheets used in construction and cars. More than 32.2% comes from electronics, where polycarbonate film is very important.

Suzhou UNIKING New Material Co., Ltd. makes high-quality polycarbonate for many industries. Their polycarbonate film and sheet products are strong, clear, and safe. They use advanced machines to make sure every batch is the same and reliable.

You can pick from many types of polycarbonate, like PC sheets and PC/ABS alloy. Their products work well in cars, electronics, and medical uses. They help you find the best solution, whether you need strength, clarity, or heat resistance.

Many customers trust their polycarbonate film for tough jobs. Every product is tested in their special lab to meet your needs. Their team gives fast service and expert help, so you get great results.

Tip: If you want strong, clear, and safe materials for your next project, contact Suzhou UNIKING New Material Co., Ltd. They are ready to help you with advanced polycarbonate solutions.

Polycarbonate is made using a careful process. First, workers get Bisphenol A and phosgene ready. These chemicals mix together in a safe place. They react and make polycarbonate resin. The resin goes to a machine for extrusion. It turns into sheets or small pellets. Workers check the resin at every step. They look for problems or mistakes. Quality control makes sure there are no bad parts. In the last step, the polycarbonate is shaped into products. These products can be thermal insulation panels.

Step | Description |

|---|---|

1 | Raw material preparation: Bisphenol A (BPA) and phosgene are combined in a controlled reaction. |

2 | Polymerization: The prepared materials are fed into a reactor where chemical reactions occur to form polycarbonate resin. |

3 | Extrusion: The resin is extruded into sheets or pellets, monitored for physical properties. |

4 | Quality control: Testing for impurities and defects using analytical techniques. |

5 | Further processing: Molding or shaping the polycarbonate into the final product, with additional quality checks. |

Suzhou UNIKING New Material Co., Ltd. uses special twin-screw machines. These machines help make strong and steady polycarbonate every time.

Polycarbonate must meet high standards. Many tests check if it is good enough. Mechanical tests see how strong it is. Thermal tests check if it can handle heat and cold. Optical tests make sure it is clear and lets light through. Electrical tests check if it is safe for electronics. Environmental tests show if it lasts in bad weather.

Quality control uses special methods and charts. Workers watch the glass transition temperature and ash data. These checks help keep the polycarbonate the same every time. Suzhou UNIKING’s lab follows CNAS rules and uses ASTM and ISO tests. You can trust their polycarbonate to be safe and strong.

Tip: Certified polycarbonate means you know it is safe and works well.

Caring for the earth is important. Suzhou UNIKING New Material Co., Ltd. uses green ways to make polycarbonate. They recycle more to help the planet. Their factories use less energy and make less pollution. The company looks for new materials that are better for nature. They study the whole life of polycarbonate to lower harm.

Sustainable Practice | Description |

|---|---|

Recycling Technologies | New processes enhance recyclability and biodegradability. |

Energy-efficient Production | Optimized conditions and catalysts lower energy use. |

Bio-based Alternatives | Research focuses on eco-friendly materials. |

Life Cycle Assessments | Evaluations minimize impact throughout product life. |

Renewable Resources | Bio-based polycarbonates decrease fossil fuel use. |

Renewable Energy | Solar and wind power support manufacturing. |

Zero-waste Principles | Waste is diverted from landfills through recycling. |

CO2 Technology | Carbon dioxide replaces some fossil-based resources. |

Suzhou UNIKING works hard to protect the environment. You get good polycarbonate and help the earth at the same time.

Glass is used in windows and screens. Polycarbonate is much lighter than glass. You can move and install polycarbonate easily. Glass is heavy and breaks if dropped. Polycarbonate does not shatter, so it keeps you safe.

Polycarbonate weighs about half as much as glass.

A 6mm polycarbonate sheet weighs 7.2kg/m². A 7.5mm laminated glass sheet weighs 15kg/m².

Polycarbonate is 200 times stronger than glass.

Glass can break and hurt people, but polycarbonate stays strong.

Polycarbonate is better for safety. People use it in car windshields and safety barriers.

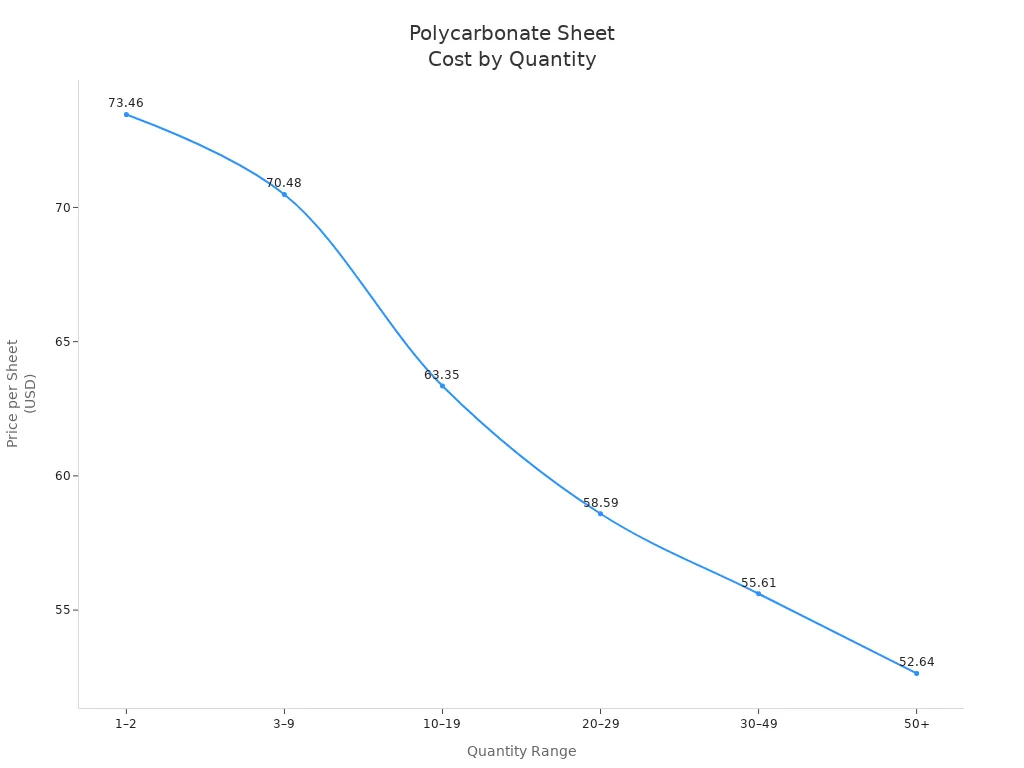

Quantity Range | Price per Sheet (Example Size) | Approximate Price per Square Foot |

|---|---|---|

1 – 2 | $73.46 | Higher cost per sq ft |

3 – 9 | $70.48 | Slightly reduced cost |

10 – 19 | $63.35 | Noticeable reduction |

20 – 29 | $58.59 | Further reduction |

30 – 49 | $55.61 | Lower cost |

50+ | $52.64 | Lowest cost per sq ft |

Acrylic is a clear plastic used in signs and displays. It looks very clear and lets more light pass through. Acrylic is harder and does not scratch easily. If you want a shiny look, acrylic is good.

Acrylic lets more light through (92%) than polycarbonate (88%).

Acrylic does not scratch or wear out as fast.

Polycarbonate is much stronger and does not break easily.

Acrylic can crack or break if hit hard.

Polycarbonate is safer for tough jobs. Acrylic is best for a clear look and smooth surface.

Material | Strength and Impact Resistance | Optical Clarity |

|---|---|---|

Polycarbonate | Very strong and almost never breaks | Not as clear as acrylic |

Acrylic | Breaks more easily | Very clear and lets more light through |

Polycarbonate is great for hard jobs. Its special structure helps absorb energy and keeps you safe. It has high impact resistance, heat resistance, and good clarity. Polycarbonate works inside and outside. You can shape it in many ways. It is also good for the environment because you can recycle it.

Polycarbonate bends and lasts a long time.

You find it in safety gear, car parts, and electronics.

It stands up to UV rays and chemicals.

You can recycle polycarbonate, which helps the earth.

Tip: If you want something strong, safe, and easy to use, pick polycarbonate.

Polycarbonate is strong, clear, and lasts a long time. Many industries use it because it does not break easily. It also blocks UV rays. More people now want materials that are light and can be recycled. New coatings help polycarbonate products last even longer. Polycarbonate is safe for healthcare and food packaging. It meets strict rules. If you need something safe, flexible, and good for the earth, polycarbonate is a smart choice for your project.

People want materials that are light and easy to recycle.

Special coatings help things made from polycarbonate last longer.

Rules for safety push new ideas in medical and food products.

Tip: Suzhou UNIKING New Material Co., Ltd. can help you pick the best polycarbonate for your needs.

Polycarbonate is much stronger and clearer than regular plastic. It does not break when hit hard. You can use it where safety is important. Regular plastic cannot handle heat or tough jobs as well.

Most polycarbonate items can be recycled. Many recycling centers will take them. Choosing these products helps the environment because they can be reused.

Polycarbonate is used in safety glasses, car parts, and electronics. It is also found in medical devices. It works well when you need something strong and clear.

Polycarbonate is safe for food and water containers. It meets safety rules. Companies test it to make sure it is safe for daily use.

Suzhou UNIKING New Material Co., Ltd. uses advanced machines and strict lab tests. Their products are strong, clear, and safe.