Please Choose Your Language

+86-512-52396378

sales@szuniking.com

sales@szuniking.com

1 Longteng Rd, Tonggang Industrial Park, Changshu ETDZ, Jiangsu Province, China 215511

Views: 0 Author: Site Editor Publish Time: 2025-08-29 Origin: Site

PA66 is also called polyamide 66 or nylon 66. It is a strong plastic used in many products today. PA66 has great strength and lasts a long time. Many companies use pa66 for tough jobs. This material helps industries that need things to work well and not break.

Industry | Percentage of Total PA66 Consumption |

|---|---|

Automotive | 40% |

Industrial Applications | 25% |

Electrical and Electronics | Significant and growing |

Pa66 is important in cars, electronics, and factories. More pa66 is made every year around the world. The Asia-Pacific area makes more than half of it. When you pick pa66, you are choosing a material people trust everywhere. It works well again and again.

PA66, also called nylon 66, is a tough plastic. It is used in many industries like cars and electronics.

This material has great strength. It is good for parts that get used a lot. These parts do not break easily.

PA66 can handle high heat. It keeps its shape and strength when it gets hot. This makes it good for engine parts and electrical connectors.

It does not get damaged by chemicals. It can be around oils, fuels, and weak acids. It will not break down.

Some types of PA66 are stronger or do not catch fire easily. These types work better for special uses. They are used in important electrical parts for safety.

People call polyamide 66 PA66 or nylon 66. It is part of the polyamide family. This family has many kinds of nylon. PA66 is special because it is strong and lasts long. You see PA66 used in many machines and tools. It works well when parts need to be tough.

PA66 is made by mixing hexamethylenediamine and adipic acid. These chemicals join together and make long chains. The chains form a strong polymer. This material does not wear out fast and can handle heat. Many industries pick polyamide 66 for parts that must last.

Tip: PA66 is trusted because it is both stiff and bendable. This comes from its semi-crystalline structure.

Nylon 66 has a special chemical structure. Each part has six carbon atoms from hexamethylenediamine. It also has six carbon atoms from adipic acid. The formula for nylon 66 is (NH-(CH2)6-NH-CO-(CH2)4-CO-)n. The "n" tells how many parts join to make the chain. This structure makes nylon 66 strong and steady.

Here is a table to show how PA66 and PA6 are different:

Property | PA6 | PA66 |

|---|---|---|

Molecular Structure | 6 carbon atoms | 8 carbon atoms |

Molecular Weight | Lower | Higher |

Degree of Crystallinity | Lower | Higher |

Mechanical Strength | Good | Superior |

Temperature Resistance | Moderate | High |

Chemical Resistance | Moderate | High |

Moisture Absorption | Higher | Lower |

Cost | Lower | Higher |

PA66 has more crystallinity and is stronger than PA6. Nylon 66 also stands up to chemicals and heat better. These things make PA66 good for hard jobs.

Polyamide 66, or PA66, is a good choice for engineering plastics. Its chemical structure helps it work well in many places.

Pa66 is known for being very strong. It makes tough parts that last a long time. Nylon 66 has strong bonds inside it. These bonds help pa66 not break or bend easily. Many companies use pa66 for gears and fasteners. They also use it for parts that hold things together.

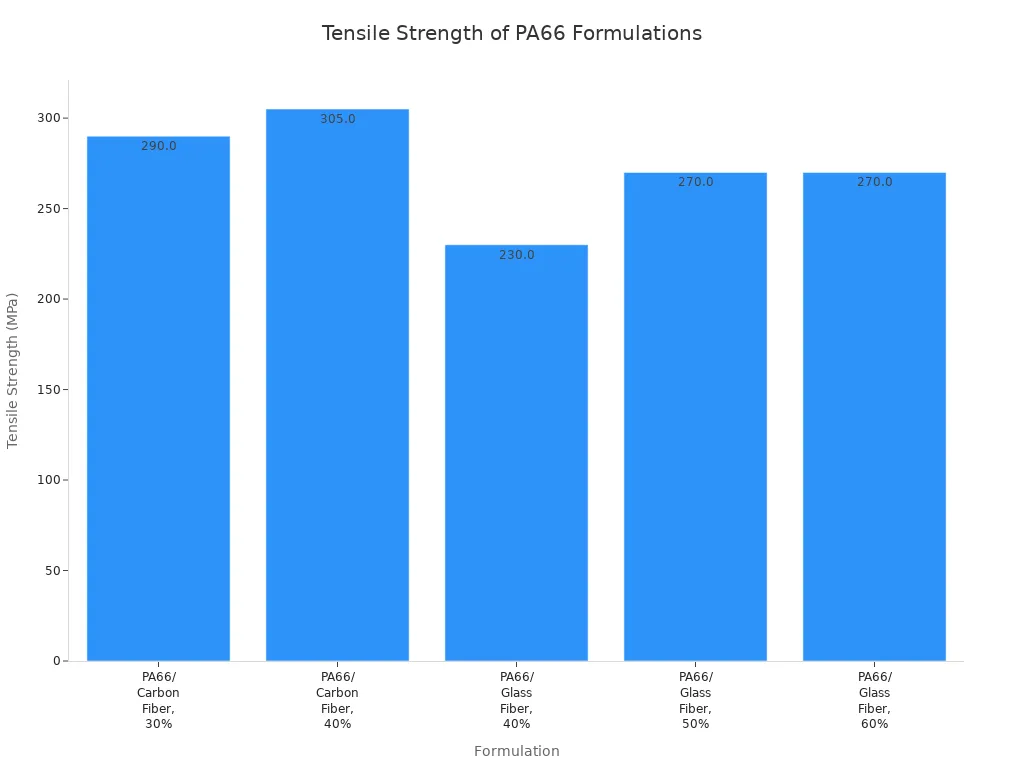

Here is a table that shows how strong different pa66 types are:

Formulation | Tensile Strength (MPa) |

|---|---|

PA66/Carbon Fiber, 30% | 290.0 |

PA66/Carbon Fiber, 40% | 305.0 |

PA66/Glass Fiber, 40% | 230.0 |

PA66/Glass Fiber, 50% | 270.0 |

PA66/Glass Fiber, 60% | 270.0 |

Pa66 gets even stronger when mixed with fibers. Even regular pa66 is strong and does not break easily:

Formulation | Yield Strength (MPa) |

|---|---|

PA66 | 45.0 |

PA66, 30% Glass Fiber | 100.0 |

PA66, Impact Modified | 35.0 |

Pa66 is stronger than many other plastics. Here is a quick chart to compare them:

Property | PA66 | PA6 | POM |

|---|---|---|---|

Tensile Strength (MPa) | 80 - 95 | Lower than PA66 | Lower than PA66 |

Flexural Modulus (MPa) | 2800 - 3200 | Lower than PA66 | N/A |

Impact Resistance | Higher than PA6 | N/A | More impact-resistant |

Thermal Stability | Excellent | Lower than PA66 | N/A |

Tip: Pick pa66 if you need parts that must not break. It is tough and works well for hard jobs.

Pa66 can handle high heat without melting. You can use nylon 66 in hot places. This is why it is used in cars and electronics. Pa66 melts at about 255°C to 265°C. It keeps its shape up to 75°C. These numbers show pa66 stays strong when it gets hot.

Property | Value |

|---|---|

Melting Point (°C) | 255-265 |

Heat Deflection Temperature (°C) | 75 |

Pa66 works better than other nylons in hot places. Nylon 66 stays tough and does not break when hot. It does not change shape or get weak over time. Pa66 is good for engine parts and electrical connectors.

Pa66 handles heat better than PA6.

Pa66 keeps its strength when it gets hot.

You can use pa66 for parts that get hot and cool many times.

Pa66 does not get damaged by many chemicals. Nylon 66 can handle gasoline and oils. It also stands up to weak acids and weak alkalis. This makes pa66 good for cars and machines. Pa66 does not break down when it touches these chemicals.

Chemical Resistance | Limitations |

|---|---|

Gasoline | High water absorption |

Lubricating oil | Must be dried before processing |

Weak acids | |

Weak alkalis |

Pa66 can handle many chemicals found in cars.

Nylon 66 does not react with most oils and fuels.

Dry pa66 before using it for best results.

Note: Pa66 is great with chemicals, but it can soak up water. Always keep pa66 dry and store it the right way.

Pa66 is great for parts that move a lot. You can use pa66 for gears and bearings. It helps parts slide easily and not wear out fast. This means your parts last longer and do not need to be replaced often.

Pa66 does not wear down quickly.

Nylon 66 stays hard and strong over time.

Pa66 is good for parts that rub together.

If you want strong parts that last, pick pa66. It is great for jobs where parts move and get hot.

Tip: Pa66 is strong, handles heat, and does not wear out fast. This makes it perfect for parts that work hard and move quickly.

Pa66 is used in many car parts. It is strong and works well. Nylon can replace metal in important parts. This makes cars lighter and saves fuel. Pa66 is found in engines, connectors, and fuel systems. Nylon does not melt or break from heat or chemicals. It is good for tough jobs under the hood.

Here is a table that shows car parts made with pa66 and why nylon is picked:

Component Type | Examples of Parts | Reasons for Using PA66 |

|---|---|---|

Engine Parts | Air intake manifolds, radiator end tanks, cylinder head covers | High thermal stability, mechanical strength, chemical resistance |

Electrical and Electronic Components | Connectors, wiring harnesses, battery housings | Excellent insulation, withstands high temperatures |

Exterior Parts | Mirror housings, grilles, trim | Durability, weather resistance, aesthetic versatility |

Interior Components | Door handles, armrests, seatbelt parts | Strength, flexibility, impact resistance |

Fuel System Components | Fuel line connectors, fuel pump parts | Chemical resistance, dimensional stability |

Pa66 is often picked instead of metal for car parts. Nylon is trusted and saves money. Other choices exist, but pa66 is used a lot.

Nylon is important in electronics and electrical items. Pa66 is used in connectors, sockets, switches, and circuit breakers. Nylon keeps electricity safe and blocks heat. Some types of pa66 stop fires and meet safety rules.

Pa66 is used for cable ties and clamps. These parts need to be strong and keep their shape. Nylon does not get weak when hot. You can pick special types for extra strength or less static.

Tip: Flame retardant pa66 has things added to slow burning and stop melting drips. You can change how fire-safe it is to meet rules like UL 94.

Pa66 is used in many tools and products. Nylon is found in sports gear, golf clubs, kitchen tools, and medical items. Nylon is good for things that need to bend, stay strong, and not wear out.

Here is a table that shows how pa66 is used in different products:

Product Type | Applications and Benefits |

|---|---|

Sports Gear | Ski bindings, bicycle sprockets, skate frames; flexible and strong |

Golf Equipment | Club shafts with PA66 GF15; stiff and resilient |

Consumer Electronics | Power tool housings, laptop frames; flame retardant, impact-modified grades |

Kitchenware | Cutlery handles, blender jars, coffee makers; food contact-approved grades |

Industrial Components | Machined gears, rollers; withstand heavy loads and vibration |

Medical Equipment | Filter housings, test tube racks; insulated and autoclavable |

Electrical Insulators | Switch boxes, transformer bobbins; high CTI property |

Pa66 can replace metal in strong parts. Nylon blends make things stiffer and stronger. Pa66 is used in car mirrors, air brakes, valves, and furniture. Nylon helps make parts that last, are light, and work well in many places.

When you pick pa66, there are many types to choose from. Each type gives nylon special features for different uses. At Suzhou UNIKING New Material Co., Ltd., we make custom pa66 types for your needs. You can get reinforced, flame retardant, or impact modified nylon from us.

If you want nylon to be stronger, pick reinforced pa66. These types use glass fiber, carbon fiber, or minerals. Glass fiber makes nylon stiff and strong. Carbon fiber makes it even harder. Minerals like calcium carbonate or talc help nylon handle heat and stay in shape.

Reinforced pa66 types help parts last longer and work better in hard places.

Here is a table that shows how reinforced pa66 types compare:

Property | PA66-CF10 | PA66-CF30 |

|---|---|---|

Tensile Strength | +30–50% | +100% |

Flexural Strength | Good | Very high |

Modulus of Elasticity | Increased | Very high |

Heat Deflection Temp | Moderate | Substantial |

Thermal Expansion | Reduced | Very low |

You can use reinforced nylon for cars, electronics, and machines. These types keep their shape and do not wear out fast.

If you need nylon to be safer, pick flame retardant pa66. These types have special things like phosphorus or nitrogen. Flame retardant nylon burns slower and passes safety rules. You can use these types for electrical parts and power tools.

Flame retardant pa66 types pass tests like UL 94.

You can pick types with different levels of flame safety.

Tip: Flame retardant nylon helps keep your products safe and meets rules.

Sometimes you need nylon that does not break when hit. Impact modified nylon uses rubber or special fillers. These types make nylon tough and less likely to crack. You can use impact modified pa66 for things that might get dropped, like sports gear or electronics.

Here is a list of what impact modified pa66 types give you:

Better toughness

More impact resistance

Might be less flexible

Could change how you make it

At Suzhou UNIKING New Material Co., Ltd., we care about the planet. We test all pa66 types to fit your needs. You can trust our nylon for good quality and strong performance.

You can trust pa66 to be strong and handle heat. It also does not get damaged by many chemicals. This material is used in many jobs because it stays tough and keeps its shape. Here is how pa66 is special:

Property/Advantage | Description |

|---|---|

Mechanical Strength | High tensile strength for demanding applications |

Heat Resistance | Withstands high temperatures |

Chemical Resilience | Resists oils, fuels, and acids |

Pa66 changes to fit new uses because of new ideas. You can find pa66 in cars, electronics, and things at home. Picking pa66 helps make better plastics for the future.

You get higher strength and better heat resistance with pa66. This material works well in tough jobs where other plastics might fail. You can use it for parts that need to last a long time.

Yes, you can recycle pa66. Many companies collect and process used pa66 parts. Recycling helps reduce waste and supports a greener future.

You find pa66 in cars, electronics, and machines. It often replaces metal in many parts. This material helps make products lighter and stronger.

Some grades of pa66 meet food safety standards. You should always check if the pa66 type is approved for food use before choosing it for kitchen tools or containers.

You should keep pa66 dry and away from moisture. Store it in sealed bags or containers. This helps keep its strength and shape for your projects.